The Reflex Canon 70d and its equipment (tripod, soft box, microphone) allow you to take photos of your creations or make explanatory videos to document your projects.

Features

- Sensor: CMOS APS-C 20.2 Mpx

- Video: Full HD 1,920 x 1,080

Tarif réduit : 5€ / 15 min Tarif normal : 10€ / 15 min Tarif entreprise : 25€ / 15 min

The Reflex Canon 70d and its equipment (tripod, soft box, microphone) allow you to take photos of your creations or make explanatory videos to document your projects.

Features

Crédit Photo : TROTEC

Crédit Photo : TROTEC

In order to use the Trotec Speedy 300, you will need to come with your vectorised cutting file in .svg or .pdf format (CAD or graphics editing software such as Illustrator, Photoshop, etc.) and prepare only one file per sheet.

For student architects, pleaser refer to our laser cutting instruction leaflet (in French).

You can also take part in one of our training courses or come and practice your drawing at the Fablab.

It will then be necessary to run this file through the proprietary TROTEC JobControl software to start the cutting/engraving process.

All you have to do is let your imagination run wild and the machine will do the rest!

Features

Only the first 15 / 30 minutes will be charged at the time of booking. The balance is to be paid on site.

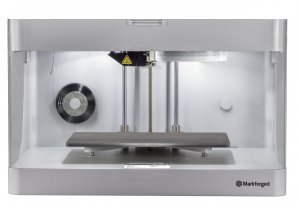

Crédit Photo : Markforged

Crédit Photo : Markforged

The 3D printer from Markforged is the first of its kind, using the new CFR technology: Continuous Fiber Reinforcement. This method, based on FDM printing, makes it possible to add, inside the printed part, continuous fibres (carbon, glass or Kevlar), which can be extruded with the help of a nozzle and thus fused with the part, giving it tenfold strength in addition to other properties, depending on the type of fibre chosen. The reinforcement strategy (number of lines, layers, orientation, etc.) can be chosen according to loading conditions.

The base material is either nylon or “Onyx”, a nylon filled with carbon micro-fibres. Onyx, when used alone, is five times stronger than ABS. With the addition of fibre reinforcement, it can offer the strength of aluminium.

Features

Printing volume: 32 x 13.2 x 15.4 cm

Layer thickness: from 0.1 to 0.2 mm

Very good dimensional stability

High strength

Rates

| Single rate | |

| Onyx or Nylon (base material) | €10 / 30 min |

| Fiberglass reinforcement | €2.40 / cm3 |

| Kevlar or HSHT* fibreglass reinforcement | €3.17 / cm3 |

| Carbon fibre reinforcement | €4.75 / cm3 |

*Optional – The volume of fibre reinforcement required is calculated when preparing the print files.

Only the first 15 / 30 minutes will be charged at the time of booking. The balance can be paid on site.

Crédit Photo : Arduino

Crédit Photo : Arduino

Arduino is an open-source platform (the plans of the board are available free of charge) programmable electronics allowing to drive inputs (sensors) / outputs (mechanical actuators, display, leds, relays, etc.) to discover electronics and to learn programming.

Features

Crédit Photo : 3D Systems

Crédit Photo : 3D Systems

This 3D Systems portable scanner allows you to digitise 3D objects with millimetre precision, while reproducing colours with a resolution of 1,920 x 180 pixels.

It comes with software that allows you to scan, rework and export the scans in .stl, .obj, .ply or .wrl.

Features